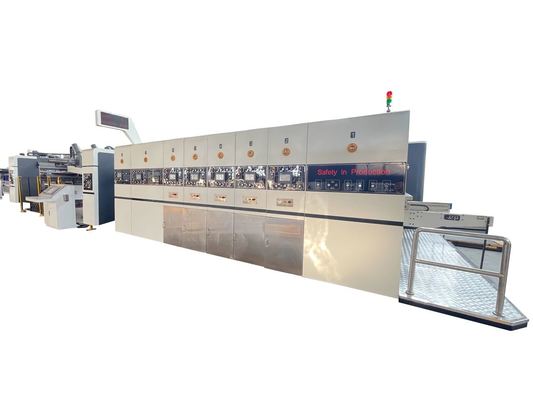

Fully Automatic Bottom Printing Carton Box Machine

Model: 1200x2400

| Inline casemaker |

| Model |

FFG-1224 |

| Printer |

| Model |

HSH-1224 |

| Max working speed |

200pcs/min |

| Max feeding size |

1200*2400mm |

| Skip feeding size |

1500*2400mm |

| Min feeding size |

300*650mm |

| Max printing size |

1100*2200mm |

| Cardboard thickness |

2-11mm |

| Register |

+/-0.5mm |

| Slotting precise |

+/-1.5mm |

| Die cutting precise |

+/-1.5mm |

| Max slotting depth |

285mm |

| Slotting interval |

260*70*260*70mm |

| |

Lead edge feeder

1.Servo control free-pressure feeding system adopted to avoid the cardboard being pressed ,improve the pressure resistance of cardboard

2.All the baffles are adjust by electric control

3.Guide rail support the right-left baffle move precise and smoothly.

4.The feeding rollers are grinded and plated with rigid chrome, make blance rectification for running stable.

5.Feeding rollers gap adjusted by PLC and touch screen

6.Firsts row of feeding rollers: Upper feeding roller diameter is 132 mm ,seamless steel covered with wear-resistant rubber treated by balance rectification.Down feeding roller diameter is 156 mm, seamless steel with knurling surface,treated by balance rectification.

7.Second row of feeding rollers:Upper feeding roller diameter is 86 mm with dia two 132mm feeding rings ,seamless steel pipe is plated with chrome and grinded surface,treated by balance rectification.Down feeding roller diameter is 156 mm, seamless steel pipe is plated with chrome and grinded surface,treated by balance rectification.

Bottom printing Printer

Vacuum transfer with doctor blade chamber:

The vacuum transfer adopted for the whole process feeding is able to feed the cardboard smoothly and precisely which improve the printing precise.

The surface of transmissioin wheel plated ceramic to increase the wearability.

Ceramic anilox and doctor blade structure.

Ceramic anilox roller external diameter is ¢212 mm,steel pipe is plated with ceramic grinded surface and laser-carved anilox

Close type doctor blade system and innovated ink-closed design to make the ink distributed very well, save ink.

Pneumatic lock, doctor blade compensition structure to make the ceramic roller touch with doctor well for good ink distribution effect

Printing roller diameter: 305mm(including 7.2mm printing plate with liner)

Printing pressing roller external diameter is ¢186mm,Steel pipe is plated with rigid chrome and grinded surface.

Ratchet wheels fixed plate axle

Loading and unloading printing template, electric controlling CW/CCW rolling by foot switch

Printing roller Horizontal movement is controlled by PLC adjustment of +/-5mm

Automatic pneumatic lifting gear working with feeding system(Anilox roller lowers down to touch printing template during feeding and rises up to leave printing template after stopping feeding.)

Printing roller circular move adopts PLC, touch screen control and inverter adjustment of 360o.(running and stopping can be adjusted)

Automatic reposition after washing the printing template during the printing procession.

Automatic ink washing system

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!