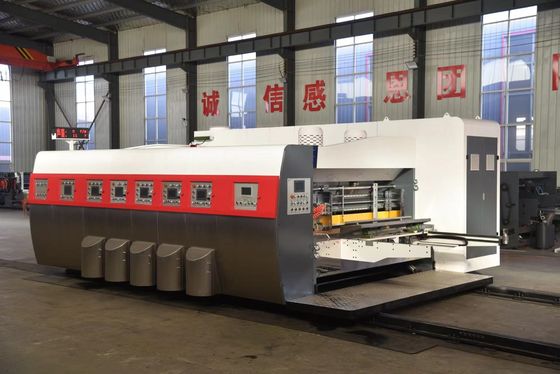

Carton Die Cutting Machine Ink Printing Slotting Die Cutting Machine

Model: 1800x2800

Feature:

The total machine adapt PLC controlling print unit and slot phase adjustment, easy to operate and reliable.

2. Whole machine frame and important part are being aging treatment, tempering eliminate the stress of metallic; all of them come from high precision processing center, CNC grinding machining process. All the rollers are high quality steel, high precision Computer dynamic balancing correction of hard chromium plating, surface grinding.

3. The transmission gear adopt 40 CrMin Ti high quality alloy steel which is grinded, and after the heat treatment ,it can up to six precision, Its surface with rockwell hardness HRC58-62, make color more accuracy.

4. Each unit of the machine with electric separation, and pneumatic locking, pneumatic total lock, to ensure the stability of the unit, and continue ring for caution when machine be separated, to ensure the safety of operating person.

A . Lead Edge Feeder

1.Vacuum transfer lead edge feeder.

2.Back buffle and side buffle are all motorized adjustment.

3.Feeder sliding block is of aluminum structure to guarantee a more stable working with less vibration.

4.Sheet counting in touch screen.

5.Skip feeding for bigger sheet.

7.Pneumatic lift device with end chain-lock switch for convenient operation.

B .Printer

1. Pneumatic clutch is provided for anilox roll, while unit is engaged in printing, the speed will be synchronized with main machine; while not engaged in printing, anilox roll can stop running, this may reduce wearing of rubber roll and anilox roll, and no need to be synchronized with main motor during cleaning.

2. Speed difference is set between rubber anvil roll and anilox roll, therefore rubber anvil roll can provide function as doctor blade.

3. Printing registration, is adjusted by computer and numeric control.

4. Traverse registration, is adjusted by computer and numeric control, at range of ±10mm.

5. Roller gap and pressure adjustment are done manually.

6. Printing cylinder left/right movement distance: 10mm.

7. Diameter of printing cylinder: ø588mm,ø600mm(with cliché thickness)

| Sheet size |

1800X2800mm |

| Design speed: |

100pcs/min. |

| Max. working speed: |

80pcs /min.(by sheet size and quality) |

| Max.working size: |

1800X2600 |

| Skip feeding size: |

2100mmX3100mm |

| Min.sheet size: |

350mmX600mm |

| Max.printing area: |

1800X2600mm |

| Cliché thickness: |

7mm |

| Slot width x Slot depth: |

7mmX400mm |

| Max. paper thickness |

10mm |

| Slotting accuracy |

±1.5mm |

| Printing registration(medium speed): |

±0.5mm |

| Mesh mode: |

Optional(120-250LPI) |

| Dimension of the whole machine |

11200(L)x4600(W)x2800(H)mm |

| Total power(KW) |

35KW |

| Total weight(Ton) |

25TONS |

C. Features of Electrical Control System

1. More than 95% electrical components of this auto flexo printer slotter die cutter and stacker are world famous brands.

2. The control center is equipped with Simens PLC and single color touch screen which come with high reliability, low failure rate, high efficiency and easy operation.

3. The main motor utilizes frequency converter to adjust speed, which is stable and power saving. Touch screen makes operation more convenient.

4. All kinds of parameters setting and display are completed by computer.

5. Phase position and slotting height is controlled by frequency converter, ensuring high precision.

6. During feeding, the ink roller will automatically down. When feeding stops, it will automatically go up. Since that, the waste of paperboard can be reduced.

7. The auto flexo printer slotter die cutter and stacker can store and memorize numerous orders. If connected with computer, the memory size will considerably increase.

8. It can also implement order and customer management as well as report printing.

9. Remote maintenance and parameter modification can be realized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!