Corrugated Cardboard Flexo Printer Slotter Machine

Model:1600x3200

Function and feature:

1. The entire machine is equipped with globally renowned computer and appliance brands.Software quality is consistent and dependable. interface between humans and machines. Touch screen control with multiple settings. The computer order management system is simple to use. Replace the order more quickly (999 orders can be stored ahead of time).

2. The entire wallboard and key parts have been aged to remove internal metal tension; high precision machining centers and CNC grinding machines have been used for grinding operations.

3. High-quality steel, grinding, very accurate computer dynamic balance correction, and surface-hard chromium plating are used for the machine shaft and roller.

4. 20CrMnTi alloy steel, carburizing, quenching treatment, hardness HRC58-62, and gear grinding processing precision level 6 are used in the engine drive gear, which guarantees the long-term use of tinted with high precision.

5. Free key connections , which reduce clearance, are used for machine transmission parts (shaft, gear joint). It works well for sustained high torque and speed.

6. The machine drive bearing and key driving components use heavy-duty self-aligning bearings, which offer long service life and easy maintenance. (three well-known domestic brands: Hava los)

7. An automatic balancing device is included in the engine lubrication system, which uses automatic spray lubrication.

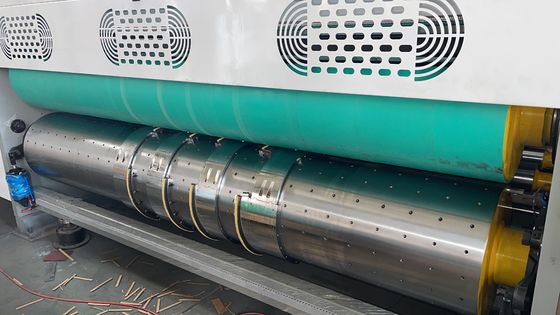

8. Beyond the clutch to guarantee the shutdown stop ink, the Chuan-ink system employs a high-precision network transmission ink roller and rubber roller, as well as an additional independent motor drive, ink pneumatic diaphragm pumps, and a pneumatic lift version.

9. Power walking, automatic locking, clutch protection, and cut-off machine

10. Oil pump spray lubrication, forged 40 cr quenched and tempered gear, grinding teeth nitriding processing, and other procedures extend the gear's service life and guarantee long-term printing color accuracy.

Basic Accessories

A. Independent Lead Edge Feeder;

B. printers

C. motorized slotter

D. Rotary Die Cutter with auto trimming device;

E. Auto Stacker

| Model |

1600x3200 |

| Machine Speed(m/min) |

200 |

| Machine Max.speed (pcs/min) |

150 |

| Machine Max.feeder Size(mm) |

1600x3200 |

| Machine min.feeder Size(mm) |

450x760 |

| Machine Max. printer size (mm) |

1500x3100 |

| thick of printer Plate(mm) |

7.2 |

| Max. slotter Dep (mm) |

560 |

| Max. Thickness of Sheet(mm) |

15 |

|

Machine size (LxWxH)

|

20852x6670x2700 |

Printers, slotters, and die cutters are crucial pieces of equipment used in contemporary manufacturing to create a variety of goods. In order to generate products like boxes, cartons, and other packaging materials, these machines collaborate to produce precisely placed cuts, printing, and slots. Reputable for producing these parts, Main Machine Tech supplies businesses worldwide with top-notch machinery.

Printers

Because they enable superior printing and branding on packaging materials, printers are a crucial component of the manufacturing process. All of the printers that Main Machine Tech offers are made to satisfy specific production requirements. Flexo printers are among the most well-liked printers that Main Machine Tech sells.

The packaging sector makes extensive use of flexo printers because of their efficiency and versatility. Paper, metal, plastic, and a variety of other materials can all be printed on using these printers. They are suitable for companies looking to stand out in the market since they can be used to print personalized graphics or logos on products.

Another well-liked printing device that Main Machine Tech sells is the UV printer. The unique UV-curable ink used by these printers yields vivid colors and long-lasting prints that can resist the stresses of packaging and shipping. They save producers money since they are less harmful to the environment and use less ink than conventional printers.

Independent Lead Edge Feeder

| Item |

Descriptions |

|

1. Lead Edge Feeding system

|

1.Vacuum transfer lead edge feeder.

2.Back buffle and side buffle are all motorized adjustment.

3.Feeder sliding block is of aluminum structure to guarantee a more stable working with less vibration.

4.Sheet counting in touch screen.

5.Skip feeding for bigger sheet.

7.Pneumatic lift device with end chain-lock switch for convenient operation.

|

| 2. Machine open/cloe |

1.Button auto control for machine open/close with alarm device to safeguard operators.

2.Pneumatic locking system, whole machine locked on fixed track by feeder main pneumatic cylinder.

|

| 3. Feeding roll |

1. Endurable rubber-coated feeding roll to add use life. |

| 4. Zero return device |

1.Computer adopts zero return device with memory function to guarantee the same adjustment standard, auto adjustment of correct position to reduce the waste of boards. |

Features of printing units

| Item |

Features |

|

1. Printing cylinder

|

1.Printing phase adjustment adopts satellite gear wheel structure, PLC control, digital display, 360 degree circumferential adjustment, stable start, correction positioning.

2.Grinded printing cylinder with harm chrome, with cross line and center line, for convenient cliché fixation and sticking, correct positioning and quick cliché registration.

3.Balance treatment, stable running, for high speed running.

4. Quick and convenient fixing system for the printing cliché.

5. Quick cliché change system to speed up the order renewal time.

6.Zero position device for printing cylinder for quick positioning of cliché change and correction, for repeated carton specification change. Foot stepping device for cliché fixation and dismantling. Phase micro adjustment.

7. Printing cylinder left/right movement distance: 10mm.

8. Diameter of printing cylinder: ø524mm,ø304mm(with cliché thickness)

|

| 2. Impression cylinder(ø156mm) |

1.Seamless steel pipe for precise processing, balance treatment for stable running, grinding and hard chromed.

2.Impression cylinder gap adopts adjustable offset ring, with close structure, precise positioning, adjustment scope: 0-12mm.

|

| 3. Feeding roll |

1.Up feeding roll: grinded and hard chromed.

2.Lower feeding roll: grinded, sand-frosted and hard-chromed.

3.Lower feeding shaft gap adjustment adopts offset ring with close structure, correction positioning, adjustable at 0-12mm.

|

|

4. Rubber roll

|

Seamless steel pipe for precise processing, balance treatment for stable running, grinding and hard chromed.

2.Steel pipe rubber-coated durable for longlife.

3.Super clutch and auto empty run device against ink dry.

4.Midheight grinding for high LPI big space printing.

5. Rubber roll open/close adopts worm gearbox manual adjustment, with worm gearbox for gap adjustment with scale indication.

|

| 5. Anilox roll |

1. Seamless steel pipe for precise processing, balance treatment for stable running, grinding and hard chromed.

2.Longlife running, anti-grinding and erosion, ideal ink transferring and controlling performance.

3.Pneumatic anilox auto elevation device and empty run device.

4.Speed difference between anilox roll and rubber roll for ink doctoring effect to increase printing quality.

|

| 6. Inking system |

1.Single-way pneumatic membrane auto circulating pump.

2. Ink filtering net to filter the dirt for nice printing result.

3.Encased ink chamber.

|

| 7. Phase adjustment structure |

1.Satelite gear wheel design.

2.Motorized circumferential adjustment, digital display, 360 degree run or stop adjustment.

3.PLC control, quick reach, convenient for cliché adjustment.

4. Manual gap Pressure adjustment for all units.

|

| 8. Printing cylinder fixed device |

1.Electromagnetic braking structure.

2.When machine unit separates or adjust phase, braking system to control the running of machine units to keep original gear positioning point.

|

| 9. Printing cylinder fixed device |

1.Electromagnetic braking structure.

2.When machine unit separates or adjust phase, braking system to control the running of machine units to keep original gear positioning point.

|

Features of slotting unit

| Item |

Features |

| 1. Slotting phase adjustment |

1.High precision inverter to adjust the speed, 360 degree adjustment, quick time.

2.Phase zero positioning device to guarantee slotting position sameness.

|

| 2. Creasing wheel |

1.Manual/motorized adjustment of creasing wheel and slotting knife head position through precise screw pole.

2.Creasing wheel down shaft, slotting knife down shaft adopt offset ring, close structure for precise positioning.

|

| 3. Slitting and slotting knife head |

1.Blade thickness:7mm. Imported high quality alloyed moon-shaped saw slotting blades, high hardness, high endurability, high grindability.

2.Grinded and hard-chromed slotting shaft for stable running.

3.Manual adjustment of slotting knife head, creasing wheel and slitting knife head.

4.Auto detection device of slotting shaft circumferential position, auto record of the position and guarantee the position auto return.

5. Pre-creaser fixed before slotter.

6. Front knife and back knife seated on one shaft.

|

Features for Rotary Die Cutting Unit

| Item |

Features |

|

1. Die cutting mould cylinder( Down cylinder)

|

1.Die cutting cylinder is made by high quality steel, fine grinding, hard chromed.

2. Balance treatment to increase stable running.

3.Die cutting mould fixation screws M10, hole distance at 100mm at transversal direction and 18 equal units at circumferential direction.

4.Die cutting wooden mould thickness 13-15mm(five ply), 16-18mm(three ply).

|

|

2. Rubber mat cylinder(Down cylinder)

|

1.Mat cylinder uses high quality steel, grinding, hard chromed.

2.Balance treatment for stable running.

3.Rubber mat thickness 8mm, width 250mm.

4.Rubber mat cylinder mechanical rotary direction change 40mm distance movement structure, movement speed same as the machine running speed.

5.Manual adjustment of die cutting mould gap, adjustment range: 0-16mm.

|

| 3. Phase adjustment device |

1.Satellite gearwheel structure

2.PLC and encoder control of die cutting phase adjustment for start and stop adjustment.

|

| |

|

corrugated packaging machine Tech is a significant participant in the manufacturing sector, offering companies die cutters, slotters, and printers to meet specific manufacturing requirements. The equipment provided by Main Machine Tech makes it possible to produce packaging materials quickly and effectively while also guaranteeing that superior cutting, printing, and slotting criteria are fulfilled to satisfy client requests.

corrugated packaging machine Tech has taken a proactive stance with their products in response to the growing need for ecologically friendly packaging materials. They are always creating machines with an emphasis on environmental consciousness. The devices have a function that guarantees no ink is wasted while in use, are minimal in waste output, and consume little energy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!