Corrugated Box Printer

Model:1600x2800

General descriptions of the whole machine

.Roller type lead edge feeder for precise feeding, long life and convenience.

.Main transmission gear using high quality alloyed steel through chamfered and grinding treatment for precise and stable work.

.Bearings are of Famous brand: NSK, HRB.

.Key-free rings for high precise transmission to guarantee the correct registration.

.Manual gap micro-adjustment, convenient and quick.

.Spray oil lubrication: each gearbox keeps oil for continuous spray lubrication.

Electrical auto control system:

.PLC control, auto sheet counting, speed indication, skip feeding, trouble alarming, etc..

.Main electrical parts are of Schneider or Omron or Siemens.

.Main machine start protection: no lock, no run, for wrong operation.

.Motorized walk: motorized open and close, pneumatic lock. Motorized walk with continuous alarming to safeguard the maintenance technicians. Auto braking device to ensure printing unit non-movement.

.Emergency stop: inside emergency stop on each unit to stop machine walking during maintenance.

| Model |

1600x2800 |

| Machine Speed(m/min) |

180 |

| Machine Max.speed (pcs/min) |

150 |

| Machine Max.feeder Size(mm) |

1600x2800 |

| Machine min.feeder Size(mm) |

450x760 |

| Machine Max. printer size (mm) |

1600x2900 |

| thick of printer Plate(mm) |

7.2 |

| Max. slotter Dep (mm) |

560 |

| Max. Thickness of Sheet(mm) |

15 |

|

Machine size (LxWxH)

|

21852x7370x2500 |

Chapter 1 Security Measures

1. Use according to the specification

Please use adhesives that meet the requirements: hot-melt pressure-sensitive adhesives, water-based sealing adhesives.

Please use the carton die-cuts within the flatness range allowed by the machine, such as the samples provided by the user.

Operate the device in accordance with the safety technical regulations.

If it is not used according to the regulations, there may be bodily injury or even life-threatening danger to the user and the third party, as well as equipment and other property damage.

2. Prohibited operation methods

◇It is not allowed to operate the equipment as follows

Power sources not included in the terms of use.

Use adhesives that have the right impact on the operator included in the Hazardous Goods Regulations.

Use user-modified mechanical facilities.

3. Allowed operation mode

◇Only allowed to operate equipment as follows

After reading through this operation manual for a reasonable understanding.

Follow the procedure specified in this operator's manual.

The device may only be used as specified in this operating manual. Other uses beyond the scope, such as the use of other adhesives and dangerous goods that are harmful to health beyond the regulations, are considered to be beyond the regulations.

4. Requirements for personnel

Workers on powered components must pay attention! Do not allow dangerous sports to injure yourself or others. Users may only assign work on powered components to personnel assigned to the work and they are able to:Complete work independently and reliably.

Under the supervision of a person skilled in the job after prior training.

If untrained personnel do not operate the equipment in accordance with the regulations or use the equipment not in accordance with this operating manual, the equipment may be dangerous.

Lead Edge Feeder

1. Lead edge paper feeding system which can greatly reduce the jam during the paper feeding;

2. Lateral baffle is electrically adjusted and front and back baffle is manually adjusted;

3. Paper feeding counter can set and display production quantity;

4. Paper feeding wheel is made of polyurethane possessing strong friction force and long durability;

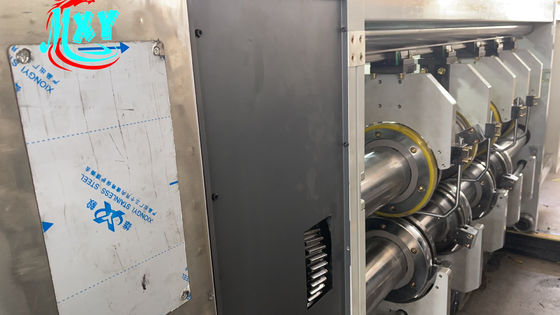

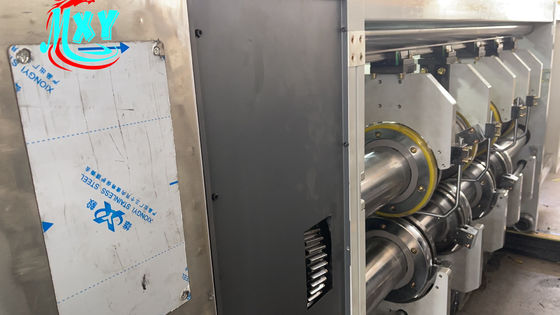

Features of printing units

1. Text encoder and electric button dual systems control the printing phase and axial position; the plate roller has the function of automatically resetting the wipe memory;

2. Each color group is equipped with an emergency stop protection switch to ensure the safety of operators;

3. The pressure of the plate roller vacuum bellows is electrically adjusted, and the suction pressure can be adjusted in sections;

4. The printing phase is equipped with an electromagnetic clutch brake mechanism, and the gear position is automatically locked when the machine is separated to prevent the zero position of the plate roller from being lost;

5. The pedal switch of the printing plate device can quickly hang and adjust the plate, which is convenient for plate changing and scrubbing, and the operation is simplified;

6. Customers with additional paper feeding roller mechanism can choose vacuum adsorption paper feeding and roller transmission according to specific products, which saves energy and reduces consumption;

7. Optional upper oil part.

Features of slotting unit

Scorer wheel gap, turbo box electric adjustable, graduated disc display adjust range -mm. Alloy tool steel with heat treatment, grinded slot teeth, good hardness and toughness. Scorer wheel, guide wheel, slot knife seat synchronous transverse displacement, PLC touch screen and electric button dual control. Planet gear structure, absolute value plate positioning, auto zero

Features for Rotary Die Cutting Unit

1.Blade thickness:7mm. Imported high quality alloyed moon-shaped saw slotting blades, high hardness, high endurability, high grindability.

2.Grinded and hard-chromed slotting shaft for stable running.

3.Manual adjustment of slotting knife head, creasing wheel and slitting knife head.

4.Auto detection device of slotting shaft circumferential position,

.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!