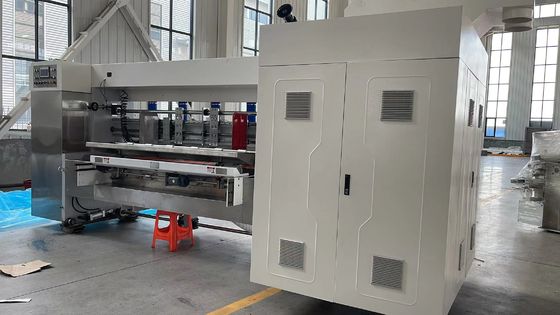

Packaging Box Printing Machine Cardboard Box Making Machine

(Two Color Printer Slotter Rotary Die Cutter In Line Case Maker Counter Ejector Delivery Conveyor)

Model:2200x5200FFG (bottom printing)

Features:

1. The bottom printing printer slotter die cutter in line case maker consists of lead edge feeder,bottom printers, slotter, die cutter in line case maker, counter ejector and delivery section.

2. All the units can move, all the rollers gap adjusted by PLC and touch screen, all the electric parts are Siemens.

3. Gears are made of 20CrMnTi,HRC 55-62, class 6 precision. Main Bearings SKF, the others are of NSK.

4. Pull roll transfer at all printing units.

5 Ceramic anilox rollers with LPI arrangements within 220-600LPI which the Buyer can choose.

5. LED display of speed and finished quantity.

Lead edge feeder

1) Servo control free-pressure feeding system adopted to avoid the cardboard being pressed ,improve the pressure resistance of cardboard

2) All the baffles are adjust by electric control

3) Guide rail support the right-left baffle move precise and smoothly.

4) The feeding rollers are grinded and plated with rigid chrome, make blance rectification for running stable.

5) Feeding rollers gap adjusted by PLC and touch screen

6) First row of feeding rollers: Upper feeding roller diameter is 132 mm ,seamless steel covered with wear-resistant rubber treated by balance rectification. Down feeding roller diameter is 156 mm, seamless steel with knurling surface,treated by balance rectification.

7) Second row of feeding rollers:Upper feeding roller diameter is 86 mm with dia two 132mm feeding rings ,seamless steel pipe is plated with chrome and grinded surface,treated by balance rectification

Down feeding roller diameter is 156 mm, seamless steel pipe is plated with chrome and grinded surface,treated by balance rectification.

Bottom Printers

Pull roll transfer

a) The pull roll transfer adopts for the whole process feeding can feed the cardboard smoothly and precisely;

1) Roller undergoes grinded and plated with rigid chrome, make the balance rectification for running stable

2) Ceramic anilox roller external diameter is 330¢mm, for solid printing and high graphic printing(220-600lpi optional);

3) Single blade chamber doctoring blade system with airbag support to meter the ink volume for even inking result.

4.) Printing roller diameter: mm (including 7.2mm printing plate with liner)

5) Printing pressing roller external diameter is ¢186mm,Steel pipe is plated with rigid chrome and grinded surface.

6) Ratchet wheels fixed plate axle

7) Loading and unloading printing template, electric controlling CW/CCW rolling by foot switch

8) Printing roller Horizontal movement is controlled by PLC adjustment of +/-5mm

Automatic pneumatic lifting gear working with feeding system(Anilox roller lowers down to touch printing template during feeding and rises up to leave printing template after stopping feeding.)

9) Printing roller circular move adopts PLC, touch screen control and inverter adjustment of 360o.(running and stopping can be adjusted)

10) Automatic re-position after washing the printing plate during the printing process.

11) Automatic ink washing system.

Standard equipments:

A. Lead Edge Feeder(Servo control);

B. Two color bottom printers

C. Dual Slotter (two shafts two blades)

D. Rotary Die Cutter(Independent Servo driving)

E. Forming Section

F. In Line Case Maker Counter Ejector(hang basket structure+roller table)

G. Fully computerized control;

Technical parameters:

| Max. sheet |

2200x5200mm |

| Min. sheet |

500 x 1800mm |

| Max. Printing area |

2200x5200mm |

| Min. Printing area |

500x1800mm |

| Paperboard thickness |

3-9mm

|

| Design speed |

40 sheets / min. |

| Dimension |

39210 x 8530x2500mm |

| Cliche thickness: |

3.4mm, 3.7mm, 3.8mm,7mm |

Double Slotter ( two shafts, two blades)

1) Double shaft slotting unit consists of pre creasing wheel, first slotting, creasing wheel and second slotting

2) Creasing wheel with PU Plated for good creasing and avoiding paper crack

3) Pre creasing roller and creasing roller gap adjusted by touch screen control

4) Creasing rollers diameter:110mm,plated with rigid chrome and grinded surface,treated by balance rectification.

5) Slotting holder rollers diameter:124mm,plated with rigid chrome and grinded surface,treated by balance rectification.

6) Cast steel slotting guide plates makes slotting precise and never damage the slotting knife.

7) 9 Crsi Slotting knives

8) All the knives move and slotting holder move adjusted by PLC control

9) Slotting holder rollers gap adjusted by electric control

Die cutting unit(Independent Servo control)

Die cutter roller made of steel moulding material and plated with rigid chrome and grinded surface

1) Anvil cover roller diameter 281 mm,steel-moulding material is plated with rigid chrome and grinded surface

2) Die cutting roller and anvil cover roller gap adjust by electric control

3) Feeding roller gap adjusted by PLC and touch screen

4) The feeding rollers are grinded and plated with rigid chrome, make blance rectification for running stable.

5) Die cutting roller circular movement is controlled by PLC, touch screen control and electric numerical adjustment of 360°(running and stopping can be adjusted)

6) Depair and Maxdura anvil cover for option

7) Anvil cover repairing knife installed

8)Independent Servo driving.

Forming section

Use servo system to parallel the jumbo size paperboards to walk forward straightly. At the same time precreasing and creasing system will further precrease and crease for nice folding. Electrical fans to blow away and clear off the slotted and die cut scraps for smooth gluing and folding. This section can well match the working speed before paperboards enter the folding beams.

Folder gluer

Feeding section

1) Feeding mouth in back of die cutting unit of printer

2) Glue Spray system installed---VALCO SPRAY GLUING SYSTEM with four guns.

3) Blower install for waste cleaning

Folding section

1) Auxiliary creasing wheel in front section to ensure easy folding

2) All the transmission belts are of good quality and high wear-resistant,long time service life.

3) Convey beams lateral movement by electric control

4) Transmission belt extension can be adjusted by pheumatic system.

5) Upper and down belt speed can be adjusted to help minimize fishtail on the carton joint.

6) Vacuum suction system to make beam transference more smoothly.

7) Special disc mechanism can solve the fishtail problem effectively on the special position on the two folding beams.

Carton collection and output section

1) High speed down counting stacking, to prevent box smearing.

2) High speed plate cardboard rectification, blower to help carton dropping, pneumatic flat push to convey circularly.

3) Count-ejector unit lateral move motorized control.

4) Down stacker uses hang basket structure to transport the piled the bundles to the ground roller conveyor for strapping in the front phase. There will be an extra roller table to collect and transport the certain quantity 10pcs, 15pcs, 20pcs, 25pcs, 30pcs, 35pcs, 40pcs to the left or right strapping machine. If not in use, operator can move aide the roller table for high bundle down stacking. There will be mode switch between high bundle down stacking or low bundle roller table stacking and transportation. The extra motorized roller conveyor table can be pushed in for use or can be moved aside when high bundle is executed. The roller conveyor table height will be leveled with the hang basket programmed height.

Electric parts

Main parts

| Name |

Brand |

| Motor |

Siemens, Germany |

| Air cylinders |

SMC, Japan |

| Gears |

20CrMnTi |

| Bearings |

NSK,Japan |

| Ceramic anilox roller |

Shanghai |

| Slotting knife |

9 Crsi |

| Anvil cover |

Maxdura, Depak or CUE |

| Inverter |

Siemens, Germany |

| PLC |

Siemens, Germany |

| Servo |

Mitsubishi, Japan |

| Contactor |

Siemens, Germany |

| Button |

Siemens, Germany |

| Touch screen |

Siemens, Germany |

.......

The packaging industry has always been essential and has experienced exponential growth in the recent past. It has become more crucial than ever, given the increasing demand for packaging products worldwide. Packaging boxes have become a necessity in various industries like food and beverage, medical, consumer goods, and much more. With the growing demand for these packaging boxes, the industry has placed a high demand on the packaging box printing machines and cardboard box making machines. These machines play a vital role in the manufacturing process of packaging boxes and have drastically impacted the packaging industry.

Packaging Box Printing Machine

The packaging box printing machine is an advanced technology that is used for printing on different packaging materials, such as cardboard, paper, and plastic. The machine is designed to meet the high precision printing requirements, ensuring quality and durable prints.

The packaging box printing machine has revolutionized the printing industry, allowing printing firms to produce high-quality prints with speed and accuracy. With the traditional printing methods, producing high-quality prints was a tedious and time-consuming process. However, the packaging box printing machine has made it possible for businesses to achieve high-quality prints and increase production turnaround time.

These machines are equipped with advanced features like automatic ink supply and level monitoring, precise control systems, and efficient drying systems. The control systems ensure that the inks are evenly distributed, reducing the chances of ink smudging, while the drying systems help to expedite the printing process by ensuring that the ink dries fast.

The packaging box printing machine is highly adaptable, allowing it to print on various packaging materials of different thicknesses and sizes. Also, the machine's high-speed and precision printing capability enable it to produce a large number of boxes within a short period.

Cardboard Box Making Machine

The cardboard box making machine is an automated machine that manufactures cardboard boxes. The machine is designed to transform raw cardboard into well-structured boxes that can be used for various purposes. The machine can be used to make boxes of different designs, shapes, and sizes to meet specific customer needs.

The cardboard box making machine has made it possible for businesses in the packaging industry to produce boxes in bulk quantities, reduce the cost of production, and improve product quality. These machines are capable of meeting any order that a business may receive regardless of the quantity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!